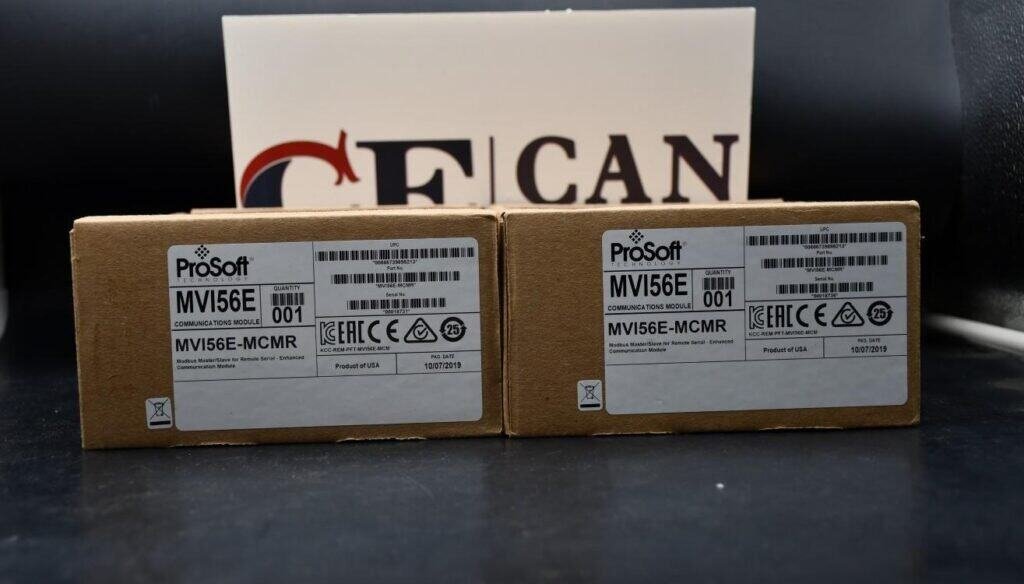

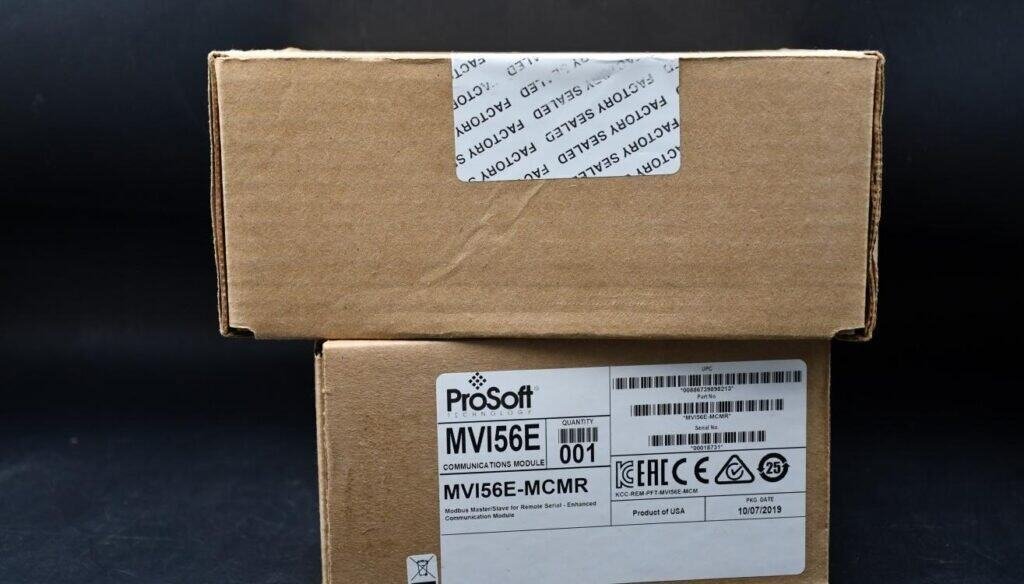

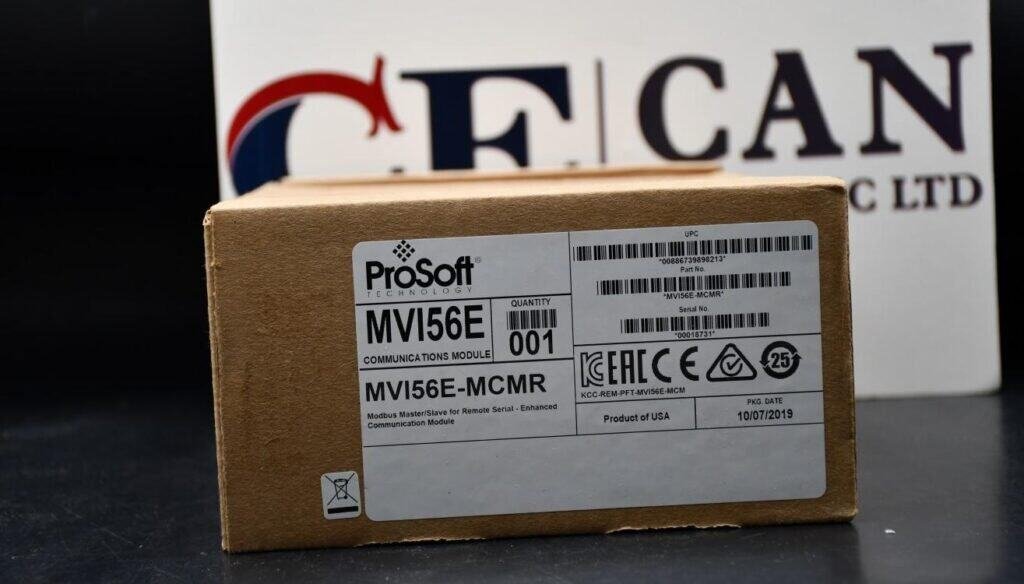

Every automation pro knows communication frustrations: A Siemens inverter + Schneider PLC “locks up” post-wiring, with red errors flashing. In humid workshops, boards corrode green; in steel mills, dust jams connectors. Crouching at 2 AM in a heavy jacket, fingers too cold to grip a screwdriver—only to find a tiny parameter drift. The MVI56E-MCMR is your reliable fix: no gimmicks, just seamless communication.

Solves Your Biggest Pain Points

Skip jargon—here’s how it fixes on-site chaos:

- Multi-brand disconnects?Before: 3 gateways daisy-chained, 4+ hours of wiring/debugging, tangled cables. After: MVI56E-MCMR clicks into Allen-Bradley 1756 chassis (Modbus/EtherNet/IP supported). Devices sync in 2 mins—cabinet clutter eliminated, debug time cut by 95%.

- Harsh environment failures?Before: Standard modules fail in 3 months (humidity/dust damage). After: Enhanced Edition (-40°C/-40°F to 85°C/185°F, IEC 60076-3 conformal coating) runs 8 months fault-free (Tangshan steel mill, outdoor installation). “More reliable than our techs,” said the foreman.

- Slow debugging?Before: 2+ hours of code editing, restarting for 1 wrong parameter. After: ProSoft Configuration Builder (graphical tool) → select device, enter IP. New equipment online in 18 mins. LED displays “Timeout”/“Address Conflict” for instant fixes (even for new hires).

- Legacy upgrade risks?Before: System rebuild ($1M+), 3-day shutdown risk, code rewrites needed. After: Drop-in replacement for MVI56 modules → 30 mins installation, no code changes. Qingdao plant swapped at lunch; data collection 3x faster by afternoon. “True plug-and-play,” noted the manager.

Proven Results, Not Hype

Field-tested stories from engineers:

Auto Plant: 3-Day Shutdown → 2-Hour DebugChallenge: Integrate 12 ABB robots → vendor warned 3-day shutdown ($32k/day loss = $96k total risk). Solution: 2 MVI56E-MCMRs (signal translation: EtherNet/IP → Modbus RTU). Results: Line restarted next day | Changeover debug: 3 days → 2 hours | Annual Savings: $192k (avoids 5 shutdowns/year). “Saved my KPIs,” said the supervisor.

Wastewater Plant: 4 Inspectors → 1 OperatorChallenge: 12 scattered pumps → 4 staff waded through storms for on-site adjustments. Solution: MVI56E-MCMR (real-time data + fault alerts to control room). Results: Staff: 4 → 1 | Flood-season failures: 3/year → 0 | Annual Labor Savings: $128k. “Sleep through storms now,” said the lead.

Pharma Plant: Data Loss → 18-Month Zero ErrorsChallenge: Fermenter communication drops → 5+ hours/week rewriting GMP records. Solution: MVI56E-MCMR (UL/CE certified, stable data transmission). Results: Data accuracy: 85% → 100% | Audit preparation time: 2 days → 30 mins | 18 consecutive months error-free. “No more all-nighters,” the engineer said.

Built for Extreme Environments

Tougher conditions = better performance:

Mining: 200m Underground LifelineChallenge: Datong mine (-15°C/5°F, thick dust) → legacy modules failed 3x/month, $72k/month downtime loss. Solution: Enhanced Edition (dust-resistant housing, wide-temperature design). Results: Faults: 3x/month → 0 in 8 months | Cart efficiency: +20% (120 → 144 units/hour) | Monthly Savings: $72k. Techs no longer carry 24/7 toolkits.

Metallurgy: Precise Signals at 120°C/248°FChallenge: Wuhan steel mill → EMI caused 5% data error, 7% billet rejection rate. Solution: MVI56E-MCMR (installed 3m from furnace, noise-filtering circuit). Results: Data error: 5% → 0.1% | Billet qualification: 93% → 98.5% | Annual Gains: $480k (reduced scrap + increased output).

Warehousing: 50 AGVs, 1 “Traffic Cop”Challenge: Guangzhou warehouse → 3 brands, data silos → 1.2% mis shipments, 20+ hours/week handling returns. Solution: MVI56E-MCMR (syncs data to WMS). Results: Mis shipments: 1.2% → 0.1% | Daily orders: 800 → 1,200 | Return Handling Time Cut: 90%. “No more rack gridlock,” said the operator.

Ports: Stable Signals 1.5km/0.9mi AwayChallenge: Ningbo Port → signal attenuation caused fluctuating weight data, 15% loading errors. Solution: MVI56E-MCMR + fiber optics. Results: Latency: 300ms → ≤50ms | Error rate: 15% → 6% | Crane output: +200 tons/day | Annual Throughput Gain: 70k tons ($420k additional revenue at $6/ton).

From mines to ports, the MVI56E-MCMR solves your urgent issues—not just tech specs. It works with any brand, any environment. That’s why pros trust it.

Over 2,000 sites in China (and 500+ globally) rely on it. Facing communication bottlenecks? → Engineers: Get the Parameter Configuration Cheat Sheet (1-page, data-focused) → Buyers: Request a custom ROI Calculator (instantly maps your costs to savings) Share your equipment list—let’s turn your data into results.

Tech Email: allen@can-electric.com (1-Hour Response, Data Sheet Included)