Your stamping machines go silent mid-shift—bleeding $22k/hour? 1783-ETAP1F hits pause.

Imagine: A halt at 2 PM grinds your line to a stop—orders stack up, your team drops everything to troubleshoot, and the clock keeps ticking on that $22k/hour loss. Traditional fixes just restart the machine, not the problem. 1783-ETAP1F breaks this cycle: it doesn’t just react to downtime—it snuffs out its root causes, putting you back in command of your floor.

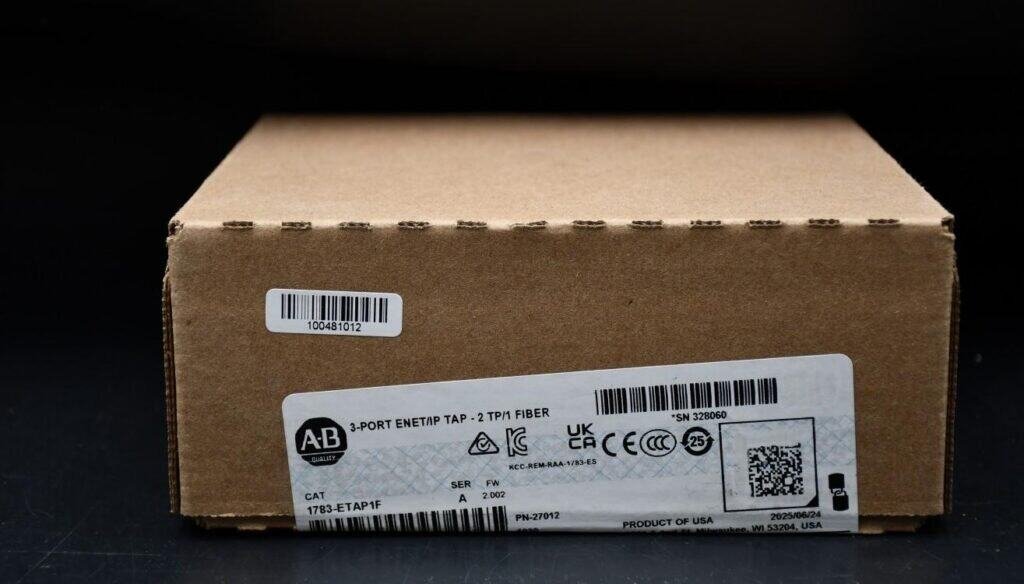

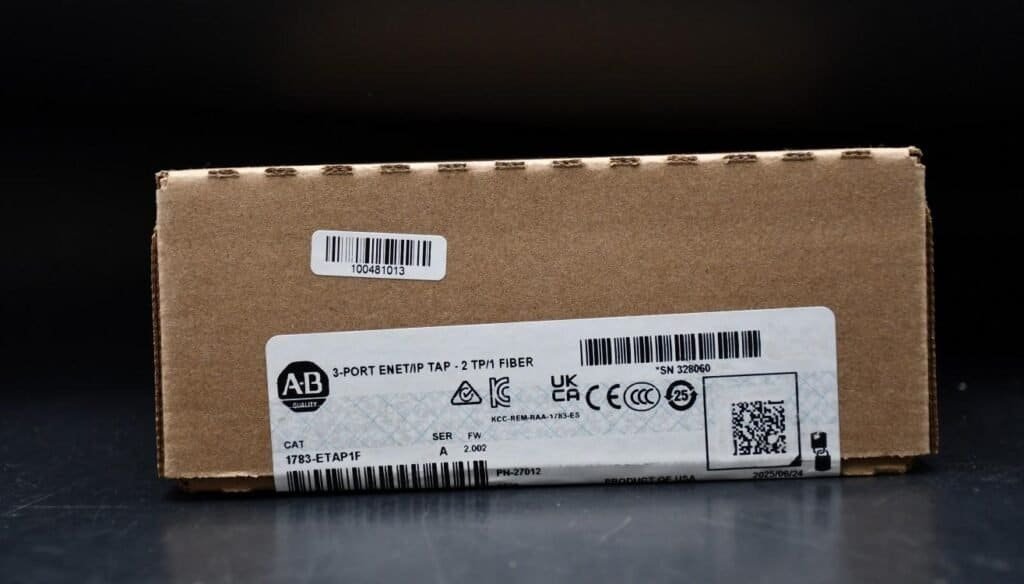

Here’s how 1783-ETAP1F stops downtime before it hits your floor

It’s a three-step safety net: You spot issues in real time, plug it into your existing systems fast, and fix problems before they flip your “production” switch to off.

1. Real-Time Visibility: Data in <50ms—No More “Guess What’s Wrong”

Grab your tablet while walking the floor—you’ll see the stamping press’s temperature spike the second it happens, or the conveyor’s pressure drop before it jams. No more huddling around outdated logs. Operational blind spots? Gone.

2. Seamless Compatibility: 40% Faster Integration—Plug In, Go

It syncs with your Siemens S7, Allen-Bradley ControlLogix—whatever’s running your line—with zero extra coding. Your tech team won’t spend 2 weeks reconfiguring; they’ll plug it in on Monday, and it’s fully operational by Wednesday. No waiting to get back to full speed.

3. Predictive Alerts: 72-Hour Heads-Up—Fix Before the Line Stops

Built-in AI combs through months of your data, then pops up an alert: “Conveyor bearing wear—service by Friday to avoid failure.” Ditch the panic of last-minute breakdowns; your team schedules maintenance during off-hours, and production never skips a beat.

38% Lower Maintenance Costs: A German Factory’s Proof

A German automotive plant cut stamping line stops from 3–4 weekly to just 0–1—all thanks to 1783-ETAP1F. Real-time data eliminated blind spots in temperature monitoring, and 72-hour predictive alerts stopped mechanical failures before they hit. In 2 months: maintenance costs dropped 38%, efficiency jumped 12%—exactly the results you’re after.

“We used to burn hours troubleshooting breakdowns. Now we fix issues before they even happen,” says Markus Weber, their production manager.

Beyond Automotive: 1783-ETAP1F Fits Your Chemical, Food, or Assembly Line

Whether you run a chemical plant (needing steady high-temp data tracking), a food facility (needing fast integration to meet hygiene deadlines), or an assembly line (needing early equipment alerts)—its 20+ system compatibility and minimal setup adapt to your workflow. No installation downtime, no forced process changes.

Ready to Stop Losing $22k/Hr? Grab Your 12% Efficiency Boost

1783-ETAP1F turns downtime losses into profits—with real-time visibility, fast integration, and zero surprise stops.

Email our industrial experts at allen@can-electric.com—we’ll send a demo tailored to your production line within 24 hours.