Tired of unplanned downtime eating $22k per hour of your profits? 1783-ETAP ends the cycle.

Is your production line stuck with frequent unexpected stops? This is exactly what 1783-ETAP is built for—turning frustration into full operational control.

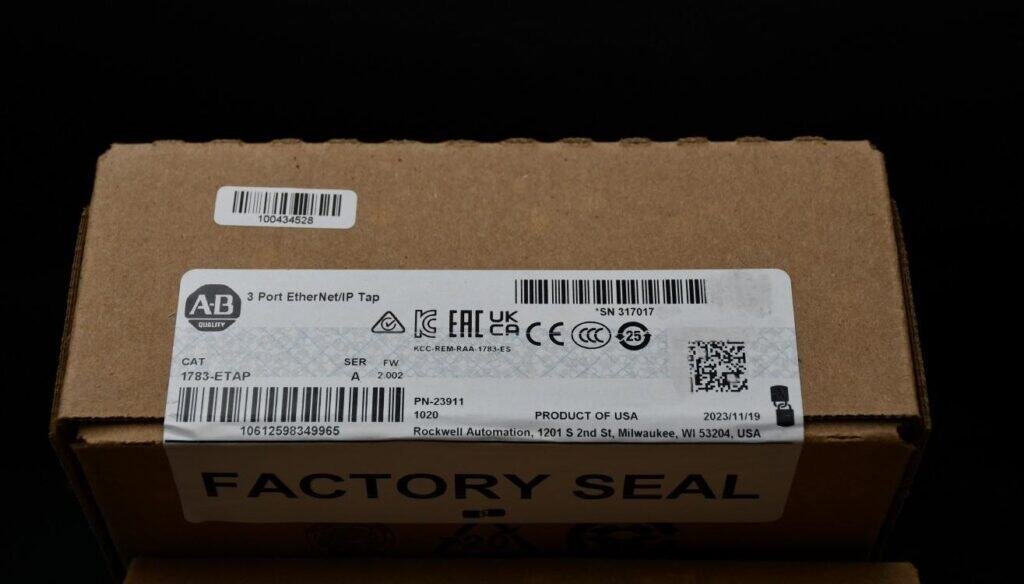

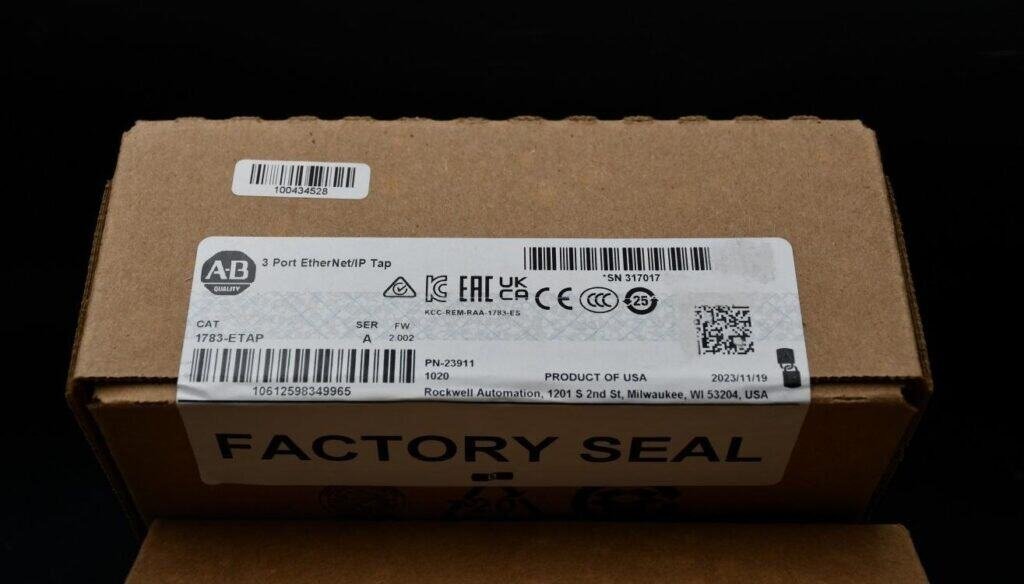

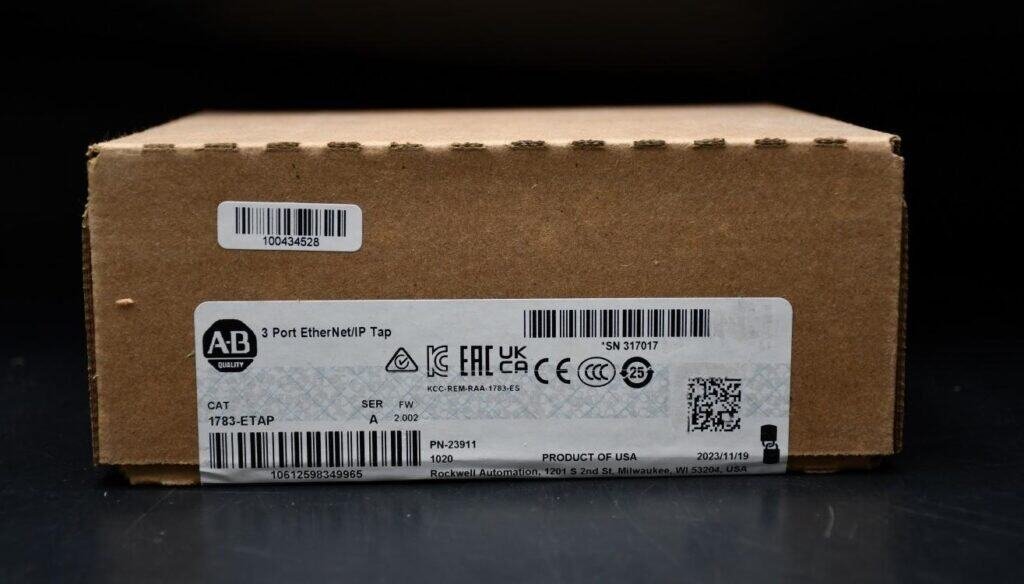

Stop firefighting—1783-ETAP fixes your downtime with 3 unbeatable strengths.

1. Real-time data visibility: Its IoT module sends operational data in under 50ms, letting you track temperature, pressure, and other key metrics on any device—no more workflow blind spots.

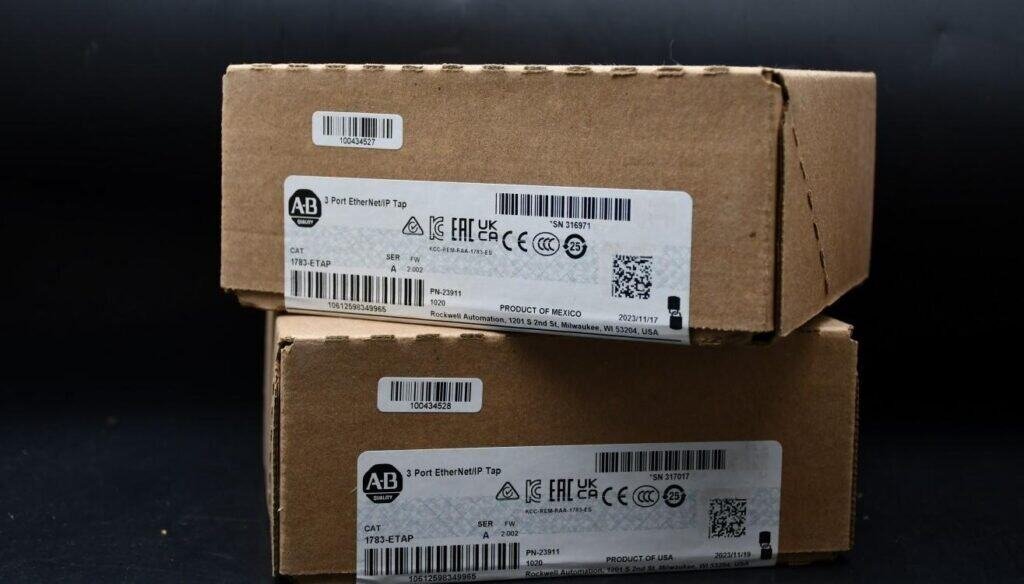

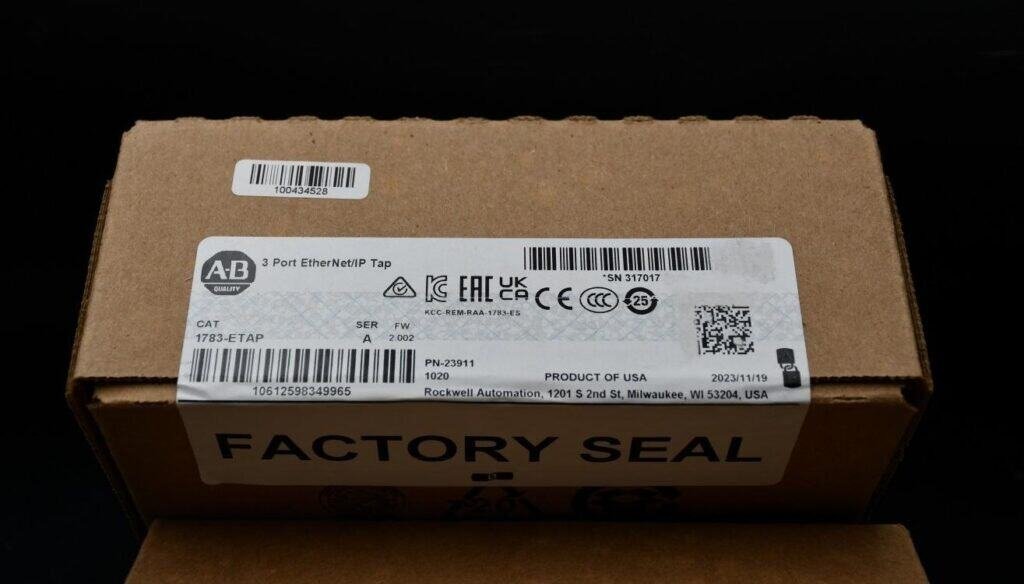

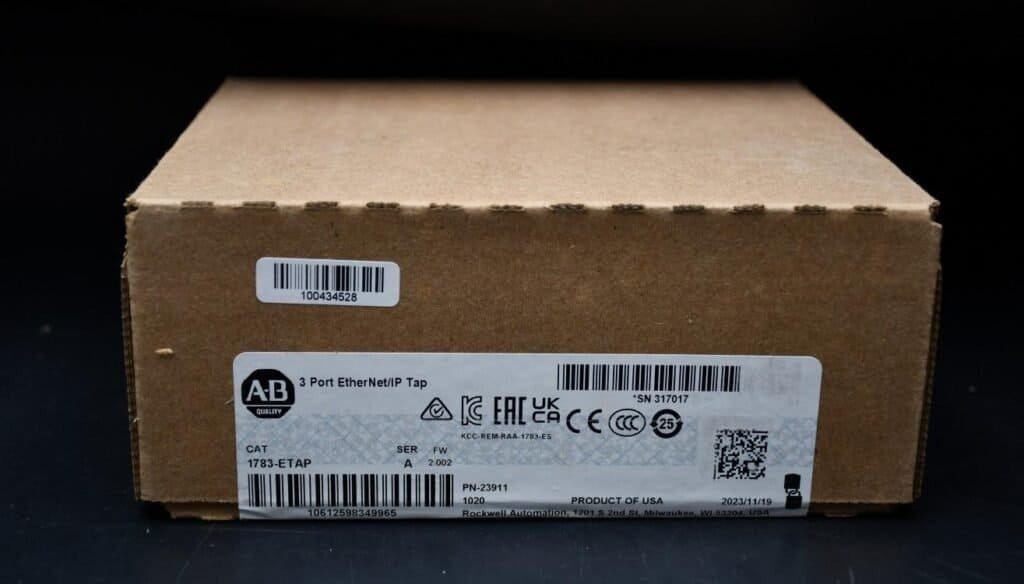

2. Seamless compatibility: It connects with 20+ major control systems (Siemens S7, Allen-Bradley ControlLogix included) with zero extra programming, cutting integration time by 40%.

3. Predictive alerts: Built-in AI analyzes historical data to warn of failures 72 hours early, shifting your team from reactive fixes to proactive maintenance.

38% lower maintenance costs—how a German factory solved downtime with 1783-ETAP.

A German automotive parts maker adopted the system and saw dramatic results: Their stamping line went from 3-4 weekly unplanned stops to just 0-1. In two months, maintenance costs dropped 38% and production efficiency jumped 12%.

“We used to spend hours troubleshooting; now we fix issues before they happen,” said their production manager, Markus Weber.

1783-ETAP isn’t just for automotive—it fits your chemical plant, food facility, or assembly line too.

It doesn’t waste time on flashy tech; it solves your real problems. Minimal setup means it adapts to your workflow without disrupting operations.

Want 12% more efficiency? Email our experts at allen@can-electric.com for a demo tailored to your production line.