In medium-scale industrial process monitoring, insufficient analog input channels (e.g., 2-4 channels can’t cover 6-8 monitoring points) often lead to complicated multi-module combinations, high costs and signal asynchrony risks. Need a 1769-IF8 analog input module perfectly matched for Rockwell 1769 series, realizing efficient 8-channel simultaneous signal acquisition?

✅ Core Advantages of 1769-IF8 (Simplified)

Tailored for Rockwell 1769 series, the 1769-IF8 supports plug-and-play with full parameter compatibility, avoiding system conflicts. Equipped with 8 independent analog input channels, it fits medium-scale multi-point monitoring needs; ±0.1% full-scale accuracy and EN 55011 Class A anti-interference performance ensure stable and reliable data acquisition in industrial environments.

✅ Rich Application Scenarios of 1769-IF8

1. Mechanical Manufacturing Industry: Ideal for multi-station processing equipment monitoring, covering spindle temperature, cutting pressure, coolant flow and other key points. 8-channel integrated design avoids signal asynchrony from multi-module combination, ensuring processing precision.

2. New Energy Battery Production: Applied in cell formation/aging workshops, collecting voltage, current, temperature of 8 battery modules simultaneously. High precision ensures accurate performance judgment; CE/UL certification meets industry safety requirements.

3. Water Treatment Industry: Used in sewage/wastewater treatment systems, collecting pH, dissolved oxygen, turbidity, water level and other indicators. -40°C~70°C wide temp range adapts to outdoor/underground environments, ensuring continuous monitoring.

4. Food & Beverage Processing: Suitable for pasteurization, filling lines, acquiring temperature, pressure, material level signals of key links. High-precision data supports process traceability and quality consistency.

5. Packaging Industry: Applied in automatic packaging lines (food/medicine), monitoring film tension, sealing temperature, filling pressure of 8 stations. Real-time acquisition reduces leakage and poor sealing defects.

✅ Practical Case: 1769-IF8 Optimizes Medium-Scale Monitoring

A European auto parts stamping factory faced 1769 system problems: 4-channel modules could not cover 7 monitoring points of stamping equipment, requiring 2 modules to be used in combination, resulting in high cost and signal delay (error >2.5%). After switching to 1769-IF8 analog input module, its 8-channel design fully covered all monitoring points, and ±0.1% high precision reduced acquisition error. The scrap rate of stamping parts dropped from 5.8% to 1.5%, saving €32,000/month in production costs.

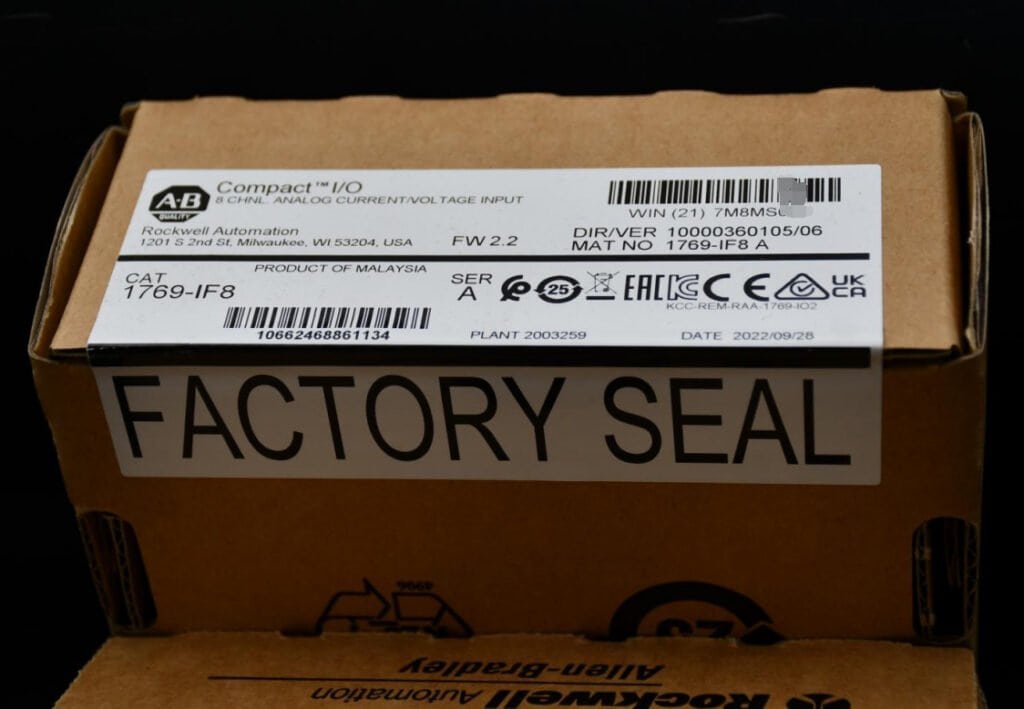

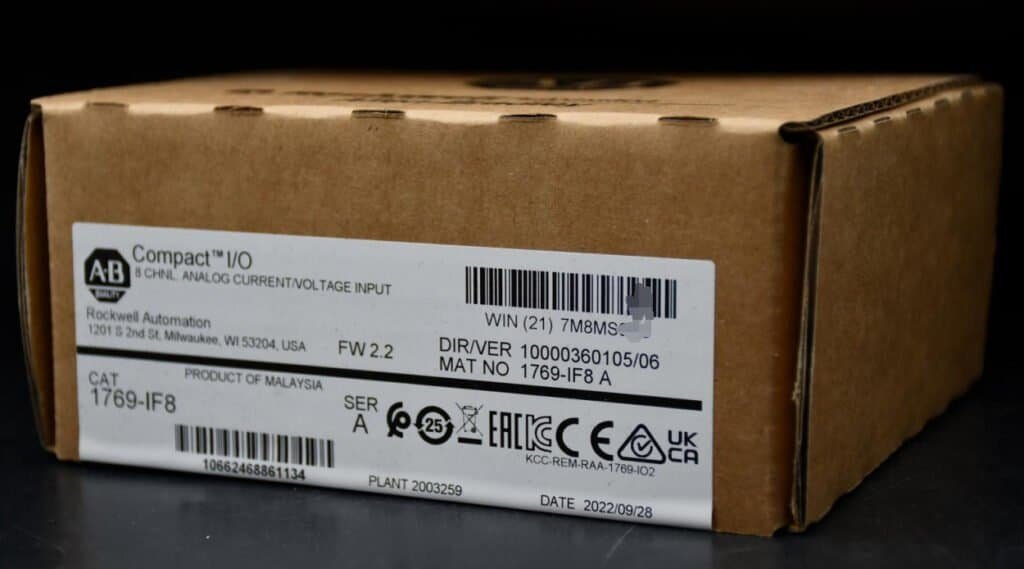

✅ Strict Certification & Reliable Quality

Each 1769-IF8 undergoes 100-hour continuous operation testing to ensure stable performance. It has passed CE, UL and RoHS certifications, and all parameters meet EU and US industrial standards, which can be safely used in overseas markets.

✅ User-Friendly Design & Low Maintenance Cost

The 1769-IF8 analog input module is equipped with independent channel status indicators, which can quickly locate fault channels; the built-in self-diagnosis function can automatically detect signal deviations, greatly reducing maintenance time and labor costs.

✅ Contact for Detailed Documents & Quotes

For 1769-IF8 technical parameter sheets, certification documents and exclusive quotes, please email: allen@can-electric.com. Mention this article to enjoy a 30-day limited discount! Our professional technical team will reply within 24 hours and provide one-on-one matching guidance.