Power Module Woes? 1756-PB72 Cuts the Cost

3 AM: Your packaging line dies from a faulty power module. 100 unsealed snacks spoil, and your $8k/hour line bleeds cash. You know the cycle: humid floors corrode modules, hot bays fry circuits, new parts clash with Rockwell systems. The 1756-PB72 ends this—permanently.

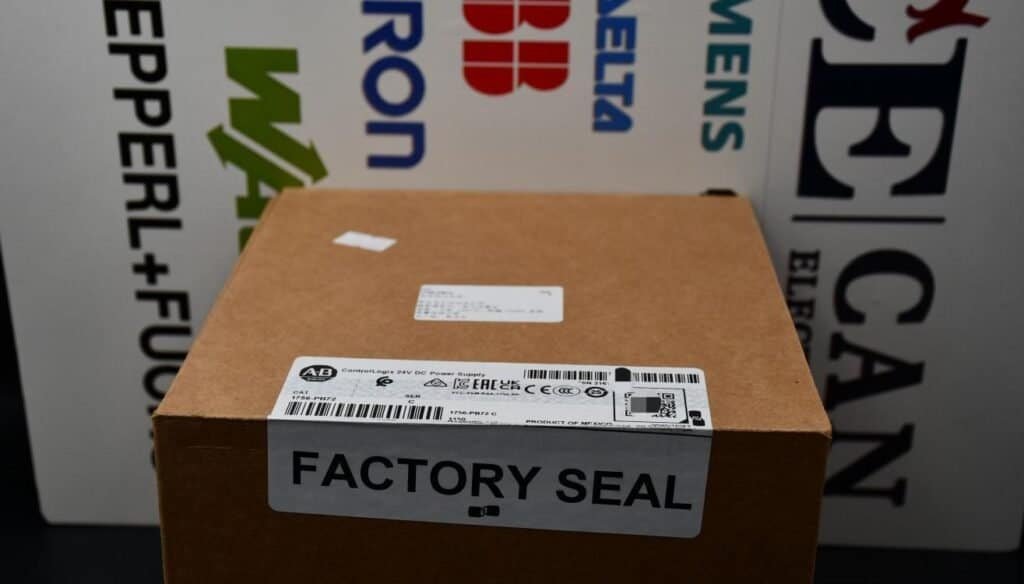

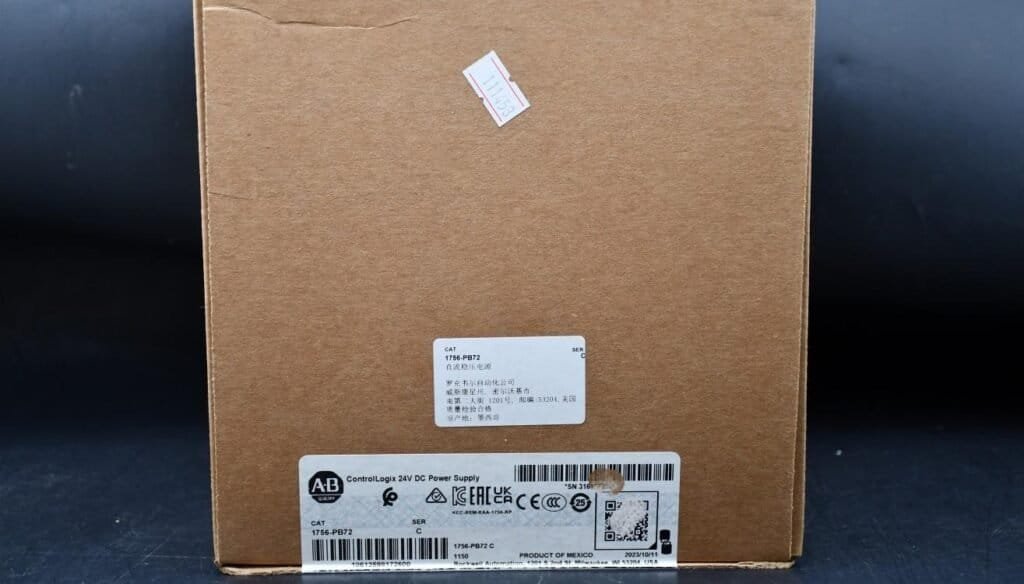

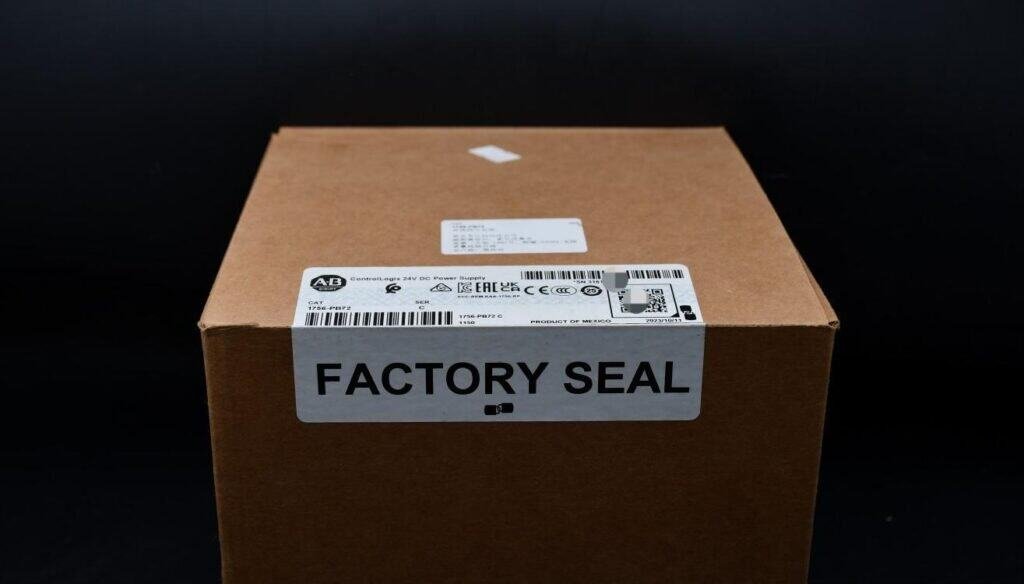

1756-PB72: Manufacturing’s Power Fix

Built for tough floors (food processing, die-casting), the 1756-PB72 eliminates power stress with key strengths:

- Harsh-Environment Durability: IP20 resists bakery dust and meat-plant moisture; -20°C to 60°C adaptability stops environment-related failures.

- Stable 10A Power: Runs sterilizers, conveyors, labelers smoothly. ±0.5% voltage precision cuts faulty seals and waste.

- Rockwell Compatibility: Plug into Logix systems, confirm, and resume in 5 minutes—no IT delays or confusing manuals.

Case Study: Ohio Plant’s Zero Downtime Win

A 50k sq. ft. Ohio food plant was losing $24k/month to 2 wasted batches from bad modules. After switching to 1756-PB72, it had 8 months of zero power-related downtime.

“We removed ‘power failure’ from our budget,” says Production Director Lisa. “Consistent logs also simplified audits.”

End Downtime—Email Us Now

Your pain: moisture, heat, or compatibility? Email sales@can-electric.com with your production type (e.g., “baking”). We reply in 24 hours—no jargon.