✅ Troubled by Low Analog Output Precision and Poor System Compatibility? Choose 1756-OF8H for European Manufacturers In industrial control scenarios like process control, equipment regulation, and automated production lines, low-precision analog output modules cause product quality deviations and high maintenance costs, plaguing European and American manufacturers. 1756-OF8H is tailored to solve these core pain points for European industrial users.

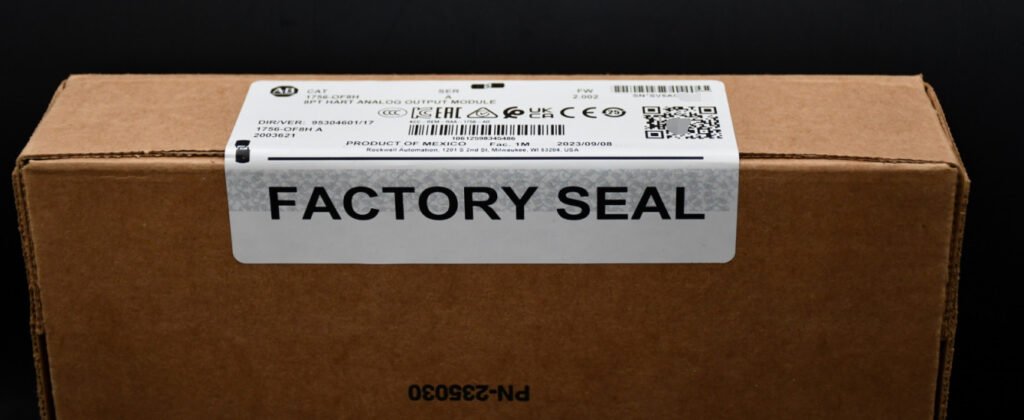

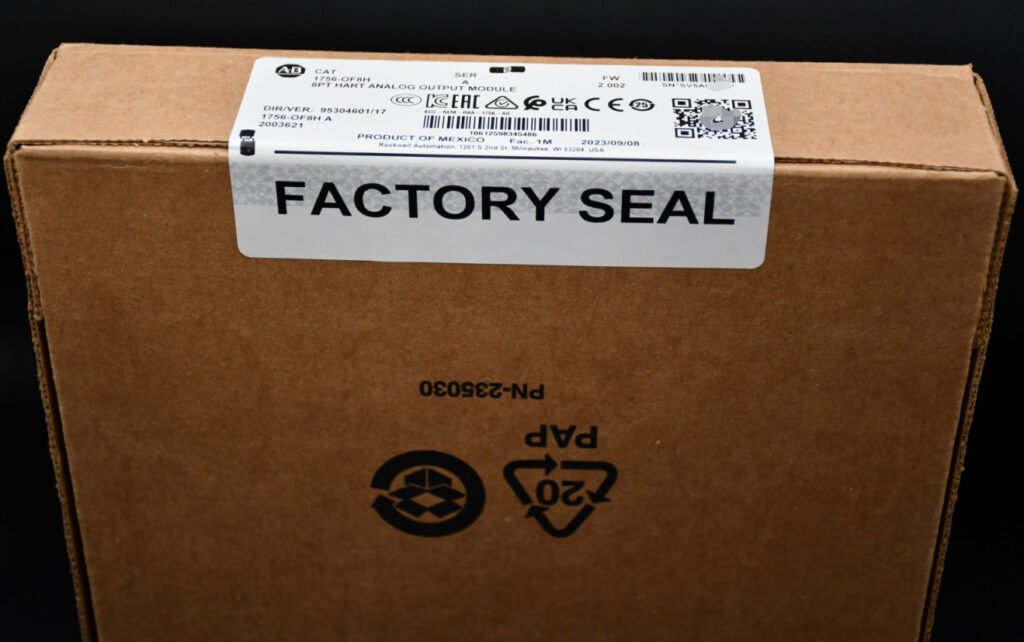

✅ 1756-OF8H: Your Trusted ControlLogix Analog Output Solution As a core product of Rockwell Allen-Bradley ControlLogix series, this 8-channel analog output module is tailored for high-precision control tasks. It effectively solves pain points of low precision, poor stability, and difficult integration, ensuring reliable analog signal output for industrial control systems.

✅ Core Advantages: High Precision & Multi-Channel Design With 16-bit resolution and ±0.1% full-scale accuracy, it provides stable and precise analog output signals (4-20 mA, 0-10 V). Equipped with 8 independent channels, it supports simultaneous control of multiple devices, improving system integration efficiency by 40%.

✅ Seamless Compatibility: EtherNet/IP Compatible Analog Output Module Fully compatible with Allen-Bradley ControlLogix chassis and processors, this EtherNet/IP compatible analog output module supports ControlNet, EtherNet/IP communication protocols. It can be seamlessly integrated into existing ControlLogix control systems without additional adaptation, reducing upgrade costs.

✅ Proven Efficacy: 1756-OF8H for German Petroleum Refinery A German petroleum refinery adopted 1756-OF8H for its crude oil distillation tower temperature and pressure control system. After 12 months of operation, control precision deviation was reduced by 90%, product qualification rate increased by 15%, and maintenance frequency decreased by 75%, perfectly adapting to the high-corrosion and high-vibration environment of petroleum refineries.

✅ Proven Efficacy: 1756-OF8H for German Pharmaceutical Factory A German pharmaceutical factory adopted 1756-OF8H for its drug synthesis reactor temperature and pressure control system. With its 16-bit high precision, the module realized stable regulation of reaction parameters (temperature deviation ≤±0.2℃, pressure deviation ≤±0.01 MPa), fully meeting GMP certification requirements. After 10 months of operation, product qualification rate increased by 18%, and manual adjustment frequency decreased by 80%, significantly improving production efficiency.

✅ Proven Efficacy: 1756-OF8H for German Food & Beverage Factory A German dairy factory adopted 1756-OF8H for its milk sterilization temperature control and yogurt fermentation parameter regulation system. The module’s ±0.1% full-scale accuracy ensured stable temperature control (65±0.3℃) during pasteurization, meeting food safety standards. After 8 months of operation, product consistency rate increased by 22%, and equipment maintenance costs decreased by 68%, fully adapting to the clean workshop environment of the food & beverage industry.

✅ Robust Design for Harsh Industrial Environments (Suitable for Power Industry) With industrial-grade anti-interference and dust-proof design, it operates stably in -20℃ to 60℃ temperature range. Equipped with overvoltage and short-circuit protection functions, it adapts to corrosive, high-vibration, and high-electromagnetic-interference environments of process industries, including power plants.

✅ Flexible Configuration for Diverse Application Needs Supports channel-specific configuration of output signal types (current/voltage) and ranges, adapting to different controlled devices such as valves, pumps, and regulators. It is widely suitable for chemical, petroleum, and power industries, as well as pharmaceutical, food & beverage, water treatment, metallurgy, and semiconductor/electronic manufacturing industries. In these sectors, it can perfectly match scenarios like pharmaceutical reactor parameter control, food sterilization temperature regulation, water treatment dosing system control, and metallurgical blast furnace pressure adjustment, serving as a reliable high-precision analog output module for various process control needs.

✅ Ideal for High-Precision Smart Factory Upgrades Supports real-time signal monitoring and diagnostic functions, seamlessly integrating with industrial IoT systems. It helps enterprises realize remote monitoring and fault early warning of analog output links, laying a foundation for digital transformation.

✅ Need a High-Precision Analog Output Module? Whether you are upgrading process control systems or building new automated production lines, 1756-OF8H can perfectly match your needs and enhance control system reliability.