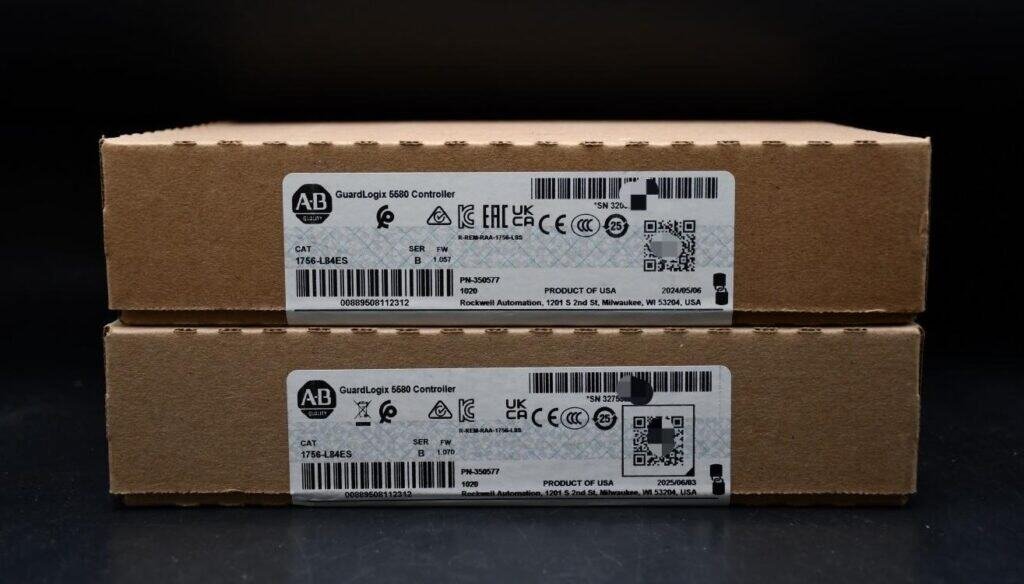

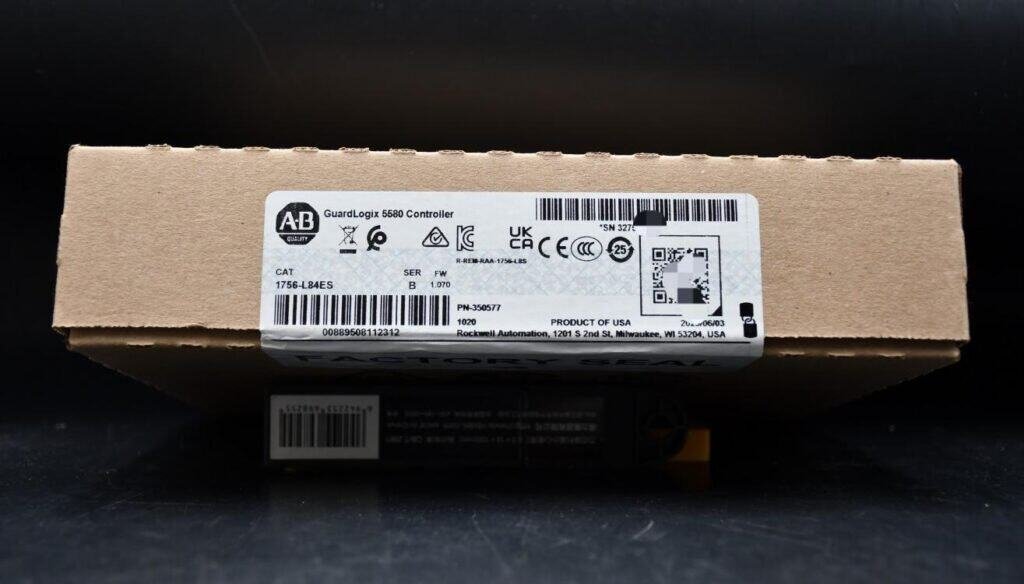

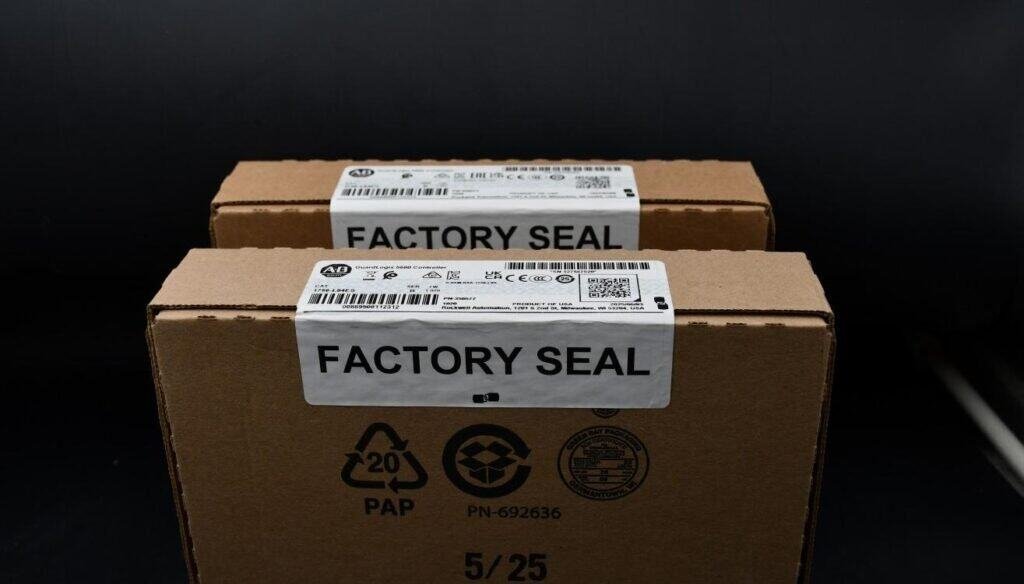

1756-L84ES GuardLogix Controller: Your Smart Manufacturing’s Game-Changer

Industry 4.0 has transformed smart manufacturing into the ultimate arena for industrial competitiveness—and the 1756-L84ES is the driving force behind winning results. Its integrated “Safety + Control + Connectivity” architecture shatters the constraints of outdated split systems, delivering robust, high-efficiency support for smart factories striving for excellence.

I. Core Capabilities: The Backbone of Smart Manufacturing

- All-in-One Safety Control: Certified to SIL 3/PLe standards, it integrates safety I/O, motion control, and networking—eliminating the need for bulky standalone safety controllers. With sub-millisecond response speeds, it guarantees top-tier protection for both personnel and equipment.

- High-Performance Processing: It simultaneously handles complex algorithms, multi-axis control, and real-time data processing, enabling dynamic production scheduling and precision that outperforms traditional controllers.

- End-to-End Connectivity: Fully compatible with EtherNet/IP, it breaks down data barriers between devices, control layers, and enterprise systems—laying a solid foundation for IIoT deployment and data-driven decision-making.

- Flexible Scalability: Its modular design adapts seamlessly from small machine control to large-scale production lines. Upgrade capabilities without replacing the core unit, significantly reducing long-term costs.

II. Value for Smart Manufacturing: From Good to Great

- Cost & Efficiency Gains: Reduced hardware requirements, faster setup, and streamlined troubleshooting minimize downtime—directly boosting production output and profitability.

- Lean Management: Real-time data empowers predictive maintenance and process optimization, elevating operations from mere “automation” to true “intelligence.”

- Future-Proof Investment: Its open architecture supports emerging technologies, ensuring your controller remains valuable as manufacturing landscapes evolve.

III. Industry Case Studies: Results That Speak Louder

- Automotive: Oversees 30+ collaborative robots and 5 flexible conveyors—boasting <5ms response time, 18% higher productivity, and zero safety incidents.

- New Energy Batteries: Delivers micrometer-level control and explosion-proof interlocking, achieving 99.5% cell yield to slash costs while boosting quality.

- Food & Beverage: Enables 10-minute packaging changeovers, cuts maintenance costs by 22%, and fully meets food safety compliance standards.

- Chemical: Powers unattended reactor control—reducing energy use by 15% and improving stability by 30% for smart, safe, and sustainable operations.

IV. Key Steps for Success

To unlock its full potential: adhere to safety certification standards, implement secure network segmentation, and train your team in maintenance and programming. These simple steps deliver remarkable outcomes.