In large-scale industrial networks, insufficient Ethernet ports, slow data transmission, poor 1756 series compatibility, or lack of network redundancy cause communication delays, device disconnections, and production monitoring failures. Need a 1756-EN4TR module to build a stable, efficient EtherNet/IP network for Rockwell 1756 ControlLogix series?

✅ Core Advantages of 1756-EN4TR (Simplified)

As a dedicated EtherNet/IP module for Rockwell 1756 ControlLogix series, the 1756-EN4TR supports plug-and-play with full parameter compatibility to avoid network conflicts. Equipped with 4 independent EtherNet/IP ports (RJ45, TCP/IP/UDP, full-duplex), this industrial communication module enables 1000 Mbps high-speed transmission and multi-device parallel connection; supports MRP/MSTP redundancy and QoS scheduling, ensuring stable data exchange in complex industrial settings. Its -40°C to 70°C wide operating temperature and EN 55011 Class A anti-interference performance adapt to harsh industrial sites.

✅ Rich Application Scenarios of 1756-EN4TR

1. Large-Scale Factory Automation Network: 1756-EN4TR acts as the core communication node for 1756 series, connecting PLCs, HMI, sensors, and actuators via 4 ports. High-speed transmission ensures real-time data interaction; network redundancy prevents production interruptions from single-point communication failures.

2. Metallurgical Industry Production Network: Applied in steelmaking and rolling lines, 1756-EN4TR builds stable communication between 1756 controllers and high-power equipment. Strong anti-interference adapts to high-dust, high-electromagnetic environments; multi-port design simplifies wiring and reduces maintenance costs.

3. New Energy Power Station Monitoring Network: 1756-EN4TR builds a hierarchical network for 1756 series in new energy stations—ports 1-2 connect PV/wind power units, port 3 connects energy storage devices, and port 4 connects grid-connection equipment. It realizes real-time transmission of power generation data to 1756 controllers and feedback to remote monitoring centers. MRP/MSTP redundancy ensures uninterrupted data transmission if a link fails; its wide temperature range adapts to outdoor harsh environments.

4. Chemical Production Safety Monitoring Network: 1756-EN4TR builds dual-redundancy architecture for 1756 safety systems—ports 1/2 pair to connect gas sensors and temperature/pressure transmitters (redundant collection), while ports 3/4 form a dedicated channel for emergency shutdown devices and safety PLCs. MRP redundancy enables <50ms seamless switchover to avoid safety data interruption; QoS prioritizes emergency alarm data for real-time controller response. Anti-interference design ensures stable communication in flammable, explosive chemical environments.

5. Municipal Infrastructure Monitoring Network: 1756-EN4TR builds a multi-point collaborative network for 1756 municipal systems—ports 1-2 serve water supply networks (pressure sensors, flow meters, pump stations), ports 3-4 serve gas supply networks (pressure transmitters, leak detectors, valves). It realizes centralized multi-region data collection and cross-region linkage, transmitting real-time data to 1756 central controllers. Network redundancy ensures uninterrupted communication, guaranteeing continuous water/gas supply and facilitating remote emergency scheduling.

✅ Practical Case: 1756-EN4TR Optimizes Industrial Communication Network

A European large chemical plant had 1756 system communication issues: the original single-port module lacked sufficient ports, causing 2-3s data delays and frequent sensor disconnections, leading to 5% production waste and €80,000 monthly losses. Switching to 1756-EN4TR enabled 8-device parallel connection via 4 ports; high-speed transmission reduced delay to <50ms, and redundancy eliminated disconnection risks. Production waste rate dropped to 1.1%, saving €69,000/month.

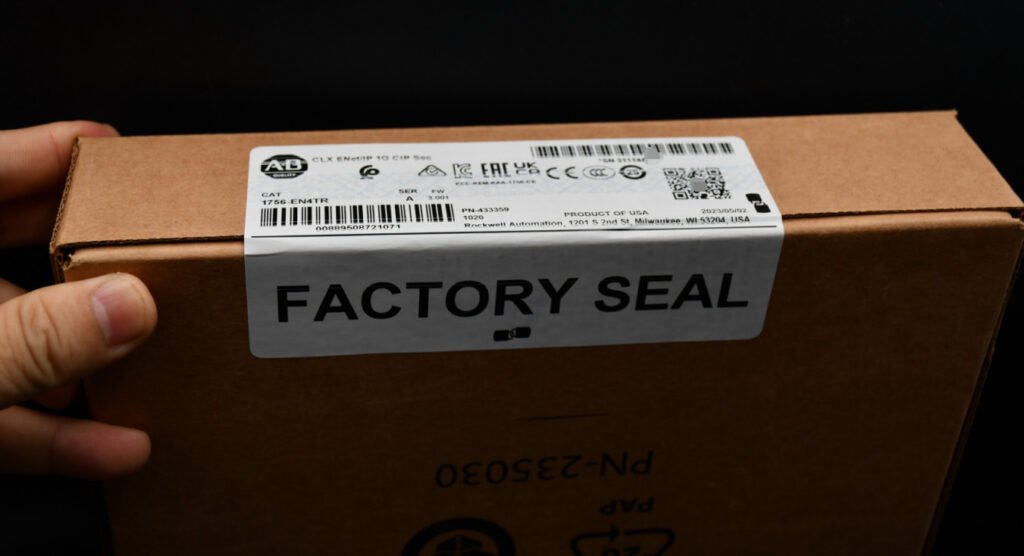

✅ Strict Certification & Reliable Quality

Each 1756-EN4TR undergoes 100-hour continuous operation testing for stability. CE, UL, and RoHS certified, it meets EU and US industrial standards for safe overseas use.

✅ User-Friendly Design & Low Maintenance Cost

The 1756-EN4TR module features comprehensive port status indicators and built-in self-diagnosis for fast network fault location. It supports online configuration and maintenance, greatly reducing downtime and labor costs for 1756 series users.

✅ Contact for Detailed Documents & Quotes

For 1756-EN4TR technical sheets, certifications, and exclusive quotes, email: allen@can-electric.com. Mention this article for a 30-day limited discount! Our professional team will reply within 24 hours with one-on-one 1756 series network matching guidance.