✅ 1756-A7: Solve Core Pain Points in Industrial Control Systems Struggling with poor scalability, unstable communication or difficult integration in industrial automation systems? 1756-A7 ControlLogix chassis is tailored for global industrial needs, addressing key issues like module mismatch, slow data exchange and unreliable operation in harsh industrial environments.

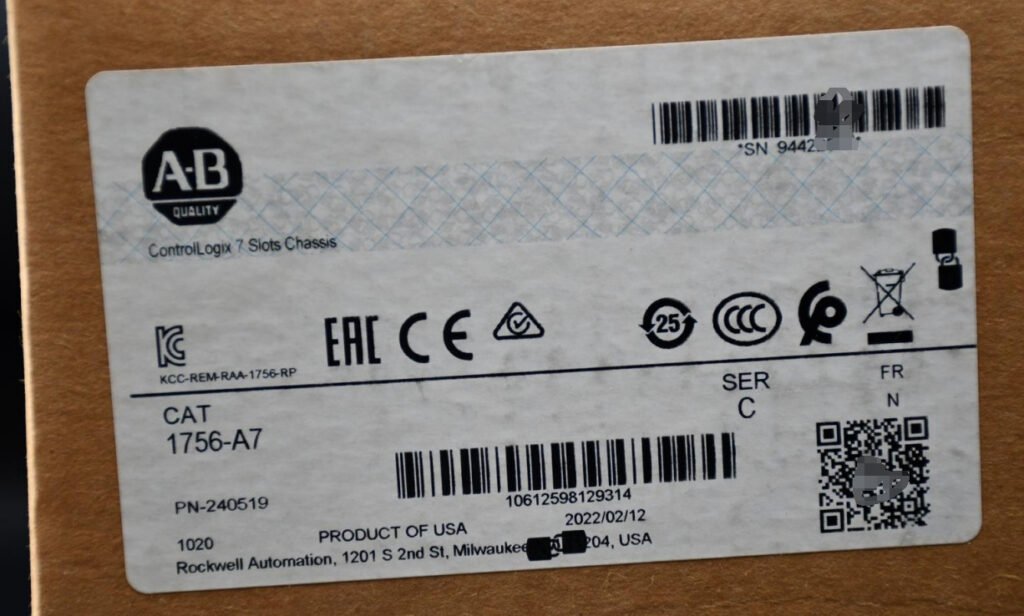

✅ 1756-A7: 7-Slot Modular Design for Flexible System Configuration Featuring 7 universal I/O slots, the 1756-A7 supports mixed installation of digital/analog I/O, communication and motion control modules—laying a flexible foundation for customized system builds. With compact dimensions (368×169×145mm) and 1.10kg weight, it adopts horizontal mounting that fits standard cabinet sizes, making it ideal for discrete manufacturing, process control and energy management scenarios.

✅ 1756-A7: High-Speed Backplane & Rugged Environmental Adaptability Built on a high-speed backplane that delivers stable power supply (1.5A@1.2V, 4A@3.3V, etc.) per slot, ensuring reliable module operation. Its rugged design tolerates 0°C-60°C operating temp, -40°C-85°C storage temp, 2g vibration and 30g shock. With IP20 protection and strong EMI resistance, it performs steadily in metallurgy, chemical and water treatment’s harsh conditions.

✅ 1756-A7: Seamless Integration & Hot-Swap for Efficient O&M Complementing its flexible and rugged advantages, the 1756-A7 natively supports EtherNet/IP, ControlNet and DeviceNet protocols, integrating seamlessly with SCADA/MES systems. The hot-swap function enables module replacement without shutdown, while compatibility with Allen-Bradley software simplifies configuration. Its low 1.8W power consumption also cuts long-term energy costs.

✅ 1756-A7 Core Value: Certified Reliability & Cost-Efficiency UL/CSA certified and compliant with IEC 60068 environmental standards, this chassis enhances system reliability and scalability. Precise power distribution and low energy consumption cut integration, maintenance and energy costs. Our global supply chain ensures timely delivery for international industrial automation projects.

✅ 1756-A7: Proven Performance in European Process Control Scenarios A German chemical plant adopted 1756-A7 as the core chassis for its process control system. Operating stably for 24 months in high-humidity/strong-interference environments, it reduced system failure rate by 72% and improved data transmission efficiency by 35%, gaining trust from European clients.

✅ 1756-A7: Customized Solutions for North American & European Markets Whether in automotive manufacturing, energy management or water treatment, our professional industrial control team provides 1756-A7 tailored solutions, perfectly matching the technical standards and application needs of global markets.

✅ Contact Reliable 1756-A7 Supplier for Global Solutions For detailed 1756-A7 product parameters or customized international adaptation plans, please feel free to contact our reliable industrial control supplier via email: allen@can-electric.com