Your Production Stalls? Blame the Underperforming Controller

When your controller lags in processing 10+ device signals, the assembly line pauses for 2-3 minutes every hour—costing $5,000 daily in downtime. You’ve struggled with more: limited I/O points forcing messy expansions, incompatible firmware clashing with Rockwell systems, slow response times ruining product precision. Your team spends hours troubleshooting instead of optimizing production. Sound familiar? Have you ever felt frustrated watching avoidable delays eat into your profits?

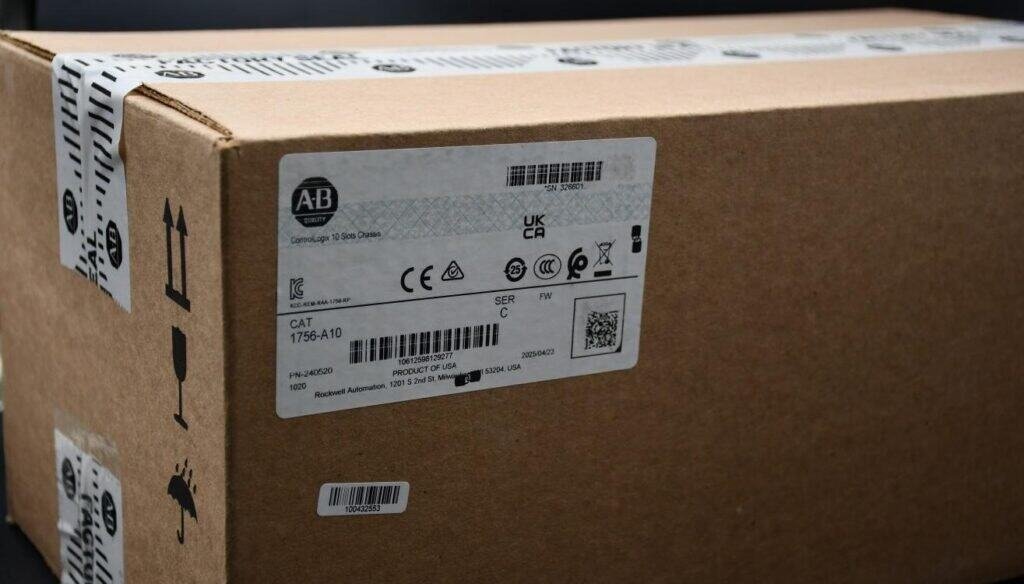

1756-A10: The Precision Solution for Manufacturing Control

Engineered for high-demand lines (auto parts, electronics, packaging), the 1756-A10 solves your core pain points with targeted strengths:

- Lightning-Fast Processing: 3.2 GHz dual-core processor handles 30+ concurrent device signals with 50ms response time—eliminating line pauses caused by signal bottlenecks. Imagine: no more 2-minute hourly stops. How much extra output could your team generate with that time?

- Flexible Expansion: Supports 8+ I/O modules (digital/analog) and 16 communication ports, adapting to production scale-ups without wiring chaos. Tired of delaying expansions because your old controller can’t keep up? This one grows with your business.

- Seamless Rockwell Integration: Preloaded Logix Control Engine 35.0 firmware syncs with Allen-Bradley drives/sensors in 2 minutes—no firmware updates or compatibility fixes needed. How much time do you waste on controller setup now? Cut that to minutes.

- Rugged Reliability: Operates stably at -40°C to 70°C with IP20 protection, ideal for cold storage and high-temperature welding shops. Does your current controller falter in extreme shop conditions? This one stays consistent.

The 60,000 sq. ft. Michigan auto plant faced 12+ hourly line pauses—sound like the headaches you’re dealing with? They swapped their outdated controller for the 1756-A10, and here’s what happened for their team (and what could happen for yours):

- Downtime dropped from 120 mins/day to 18 mins/day—saving $4,250 daily

- Part defect rate fell 12% (from 5.3% to 4.7%) thanks to precise signal processing

- Expansion of 10 new sensors took 1 hour (vs. 8 hours with old controller)

“We went from troubleshooting controllers to optimizing production,” says Jake, the plant’s Automation Manager. “The 1756-A10 pays for itself in 2 months.” Could your operation use that kind of ROI on a core piece of equipment?

Case Study: Michigan Auto Plant Cuts Downtime by 85%

Ready to End Controller-Related Headaches?

Let’s cut to your needs: What’s your biggest controller frustration? Slow processing? Can’t expand without chaos? Compatibility headaches? Email sales@can-electric.com with your answer and production type (e.g., “auto components”)—our engineers will send a tailored quote and integration plan within 24 hours. No jargon, just solutions for your line.